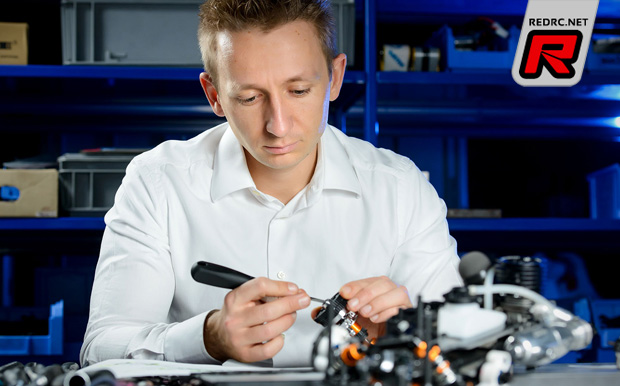

Martin Hudy talks NT1’15 – Exclusive Interview

As previously announced, today we are publishing an exclusive interview with Xray on-road designer Martin Hudy ahead of the forthcoming release of Xray’s all-new NT1 2015 200mm nitro on-road car. Our interview will shortly be followed by an exclusive write-up with more in-depth information on what racers can expect from Xray’s new 1/10th nitro car.

Red RC: The NT1 2014 Spec car featured only very subtle changes from its predecessors, yet Alexander Hagberg was able to win with it the 2014 IFMAR Worlds. Did you expect that?

Martin Hudy: Travelling to any race as a team, you cannot set your strategy and expectation to anything less than to finish at the top of the podium. There can be only one winner, and there are many teams who are able to take the win, so you need to have a bit of luck as well. Sometimes you have a lucky day and everything works for you, but sometimes you have a bad day and no matter what you do it just does not go well. Going to any race, we have full respect for all our competitors and we work very hard not only during the race itself but especially before the race.

The World Championship is the ultimate event that crowns the best of the best, and every two years all teams pull out their “secret weapons” for this race. To be honest we did not have much work to do on the NT1 before the Worlds, which is only because we have been doing our homework all the time. Since the very first NT1 released 8 years ago we have never stopped working on it and developing it, and year by year we made new improvements as they were needed. I can honestly and humbly say that the NT1 is one of the best performing nitro touring car since its release, which was recently proven by its second Worlds title. Did we expect it? Not particularly, but with the amount of work that the entire team put into last year’s platform I was very confident going into the Worlds. I knew that we can do well, but you never know when luck will be with you or not. Of course I was very nervous until the very last second when Alex crossed the finish line! This was the first World title for Alex, and it was a very well deserved victory.

Red RC: Speaking about the annually released new car, how do customers feel about that?

Martin Hudy: This is a very tricky area that every designer has to deal with. In every industry you have manufacturers improving their products: sometimes driven by fashion, sometimes driven by rule changes, sometimes by new technologies or materials or a million other factors which influence the product design and features. In high-competition racing you really cannot stop the progress of development. In some classes, development is much faster than in other (more mature) classes where development is not that fast but still the competition pushes the boundaries. To keep ahead of the pack – quite literally or figuratively – you have to follow and surpass what everyone else is coming up with. Xray is known for being very serious when it comes to ongoing product development, and it is of course a very difficult task to incorporate changes that will help to improve the car either in performance, reliability, or both. And of course you are always looking for a good balance between too much news and not enough news.

Red RC: What can racers expect from the 2015 car?

Martin Hudy: The 2015-spec version of the NT1 is our most significant update to date. It incorporates dozens of changes, essentially making it an all-new platform. The most significant change is the all-new aluminium bulkheads which replace the composite ones, making the main backbone of the car now full aluminium. Also very important is that the well-proven suspension geometry, shocks, and drivetrain have not be changed at all. There are plenty of other details I cannot disclose at this time, but you will see them soon enough.

Red RC: Why the change to aluminium bulkheads when the composite ones were obviously working for you?

Martin Hudy: Producing moulds for composite parts, especially ones as complex as bulkheads, is extremely expensive and time consuming. Over the last year we successfully used composite bulkheads which worked very well; the flex of the bulkheads generated extra traction which when combined with soft tyres made the NT1 unbeatable. However, the recent change in EFRA rules to use spec hard tyres eliminated the competitive advantage of composite bulkheads, and as such we decided for 2015 to make this significant change and go with aluminium bulkheads. Now we have the same flexibility when it comes to the rapid design changes for the main framework of the car.

Red RC: The NT1 200mm nitro car is your most successful platform, with two IFMAR World Championships, and several EFRA European, ROAR National, and Asian National Championship titles. As a designer, do you feel more pressure to retain the performance of an already successful platform, or is it harder to come up with ground-breaking ideas to boost the performance of a less-successful car?

Martin Hudy: It is definitely easier to improve an already well-performing car than to heavily upgrade a platform that is not performing so well. Luckily, all Xray cars in various classes are fully competitive with anything else on the racing market, so over the last few years we have not have to make any major updates.

As a designer, you are constantly under pressure and you need to live with the fact that you will never make everyone completely happy. For myself, travelling to all major races and being away nearly 50 weekends a year meeting with the team, customers, and our friends lets you absorb a lot of feedback, comments, ideas, suggestions, complaints and of course you need to observe the competition as well. So there is a lot of information that has to be sorted out and filtered through before we start work on anything. The team, of course, wants and needs to have a car that is at least as competitive as the rest of the competition out there … preferably better than the competition, of course! So the pressure from the team is significant, but myself being a racer I fully understand and it is also my priority to have the best performing car at every track, every race.

After we finish a new version of the car, I always say to myself that now we have achieved the stage where everything is as it should be and there is no more room for improvement. And then I laugh at myself because I already know that in the next couple of races we have some new ideas to test or we may be forced to think up new things to compensate for when rules changes (like in this case, the new “hard tyre” rule). All the new stuff we try to test is made during the racing season, and at the end we have to decide what will make it to the final new-spec car for the next year. You might be surprised that the vast majority of things we test never make it to the final product because they were not a sufficient improvement, so the majority of the time we spend testing things which ultimately do not work. Such is the reality of development.

Red RC: Xray is one of the very few manufacturers that is involved in all racing classes. How do you handle the development of so many cars?

Martin Hudy: It is true that we have grown extremely quickly in the last decade, and we have worked extremely hard. As a family, we dedicate all our energy, effort, and time to the company. Of course we could not get where we are now without the huge support of our friends, team drivers, and distributors. With the recently released the X1 we have covered the increasing F1 class, and the last project we have been working on for a very long time (and should be finished this year) is the XB2 – a 1/10 off-road 2WD. So with these we have covered off all high-competition racing classes. This year we will have a platform for each of the 12 racing classes, and yes this requires a lot of ongoing work for continuing development and to travel as a factory team to all races to back up the team and customers. With 12 classes involved – wow, that is a lot – it means that we have to (on average) come out with 1 car each month during a year. This is a huge responsibility. The team does a lot of work and helps us greatly, but at the end all the work behind the computer is our responsibility so this should give you a small brief glimpse of the amount of the work we face on a continuing basis. For a few years now I have had full responsibility for the on-road division that includes: T4, NT1, RX8, X12, X10, and now the X1. Juraj is in full charge of the off-road division that includes: XB8, XB4, XB2, XB8E, and XT8. This split in responsibility is the only way we are able to handle the entire product portfolio.

Red RC: With hand-out tyres becoming more and more popular worldwide – for example in the ENS and several other racing series – have you gained further experience during the recent season in terms car design to figure out how to extract maximum performance from the often harder compound tyres?

Martin Hudy: We had a significant experience at last year’s European Championship. With so much work on our schedule, we decided to skip the warm-up race as we already had a great performing car, great team, and of course a lot of previous experiences. Ultimately this turned out to be a very bad decision. With very limited time at the Euros, we struggled with the new hard tyre rule; we were basically at square 1 while other teams had already some basic set-up and knowledge from the warm-up race which we did not. All the knowledge and experience we had before was based on using soft tyres, and I really did not expect that we will have such a hard time finding a proper set-up within the very limited track time. So while we were quite under pressure, Alex still managed to work out the details and was fast and competitive but this time luck was not with us and Alex flamed out during a refuelling stop in the semi. So, it was the first time in a very long time that we did not have any cars in the A-main of a Euros, and that was not a very nice feeling at all. This was one of the kicks that really pushed my limits with the on-going development. We stayed with Juraj for a couple of days after the Euros so that we could practice, and we tested dozens of different flex combinations and made a lot of hand modifications to many parts to work around the problem of missing steering. After a few days we got the NT1 working well again, and we were able to get same lap times equal to the fastest ones. Of course all this is happening after the race is already over, so it pushed us to move forward and motivated us even more to move towards the all-new platform with the aluminium bulkheads which will help us to be more flexible and be better suited to the hard tyre rule.

Red RC: When looking at the current crop of 200mm cars, do you think there is any room left for innovations? On the surface they appear to differ only by the colour of the anodised parts.

Martin Hudy: Of course there is always room for improvement. As my father says: “You can never reach 100% perfection, but you need to try.” There is always some place or aspect that can be improved. Technology and design all continues to develop and we need to face not only those changes but also rule changes. Not only the 1/10 nitro touring cars, but all RC car racing categories are already very evolved and in what could be considered a “mature” stage. However, there are always new ways to approach the “problems” associated with improvements, and designers must always be mindful of staying within the rules and also staying within the “comfort zone” of racers and customers. Sometimes when radically-different ideas or technologies are introduced, the people racing the cars are very leery of them or slow to accept them, even if the ideas seem to be amazing. So I expect development to be pushed slowly here and there. Now with the aluminium bulkheads, further development & testing will be much more flexible for it is much easier to modify aluminium pieces and make a few of those for testing rather than making very expensive modifications to composite part moulds.

Red RC: Not long ago there was a push to bring 200mm and also 1/8th electric racing to life using purpose-built cars or conversion kits. Do you think this could be a future trend, or is it just a way to get rid of old stock of nitro kits?

Martin Hudy: In my opinion and from experience, the trend in general is now towards the electro classes. To race an electric-powered car is not only cheaper but also you do not need a mechanic. The newer generations of drivers want things that are “plug & play” to make for no-hassle racing … and the electric classes fulfil this desire. So I expect that the trend will continue, and electric-powered racing will continue to grow while nitro will continue to decline. And of course it is our job as a manufacturer to provide the customers with the products that are hot and in demand. We already see some 1/8 on-road electric cars, but as the racing is very limited we should soon see what will be the future of it but I would not be surprised when electronics manufacturers come up with powerful electronics for 1/8 on-road cars which would boost the popularity of that class. Hmmm … that makes me very excited for the future!