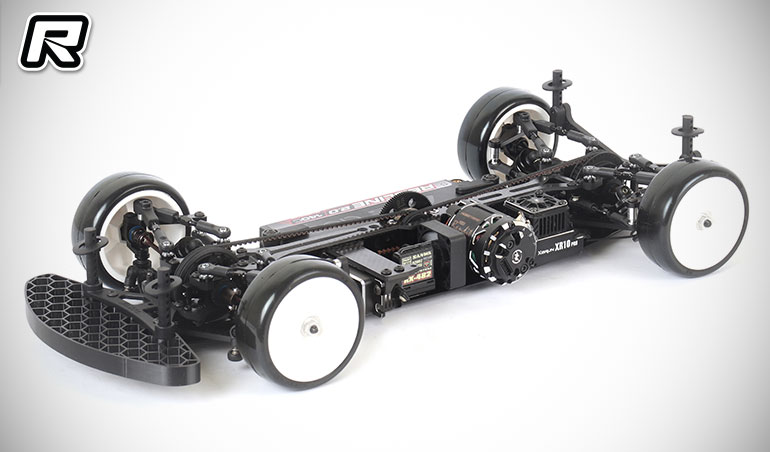

ARC A11 1:10 Electric Touring Car

Taiwan onroad kit manufacturer ARC has unveiled its latest competitive level 1:10 Electric Touring Car the A11. Having run pre-production examples of the car at the FEMCA Asia Championships just before Christmas at the 2026 World Championship host track Hongyu GDC where team driver Enrico Jung won A1 of the Pro Stock Main, the design of the all-new ARC A11 focuses on a number of main themes. ARC has worked on a simple design that makes setup and maintenance easier, a lower and more concentrated centre of gravity that optimises handling and performance, and lightweight components that maintain the necessary strength. With these key elements in mind, the A11 was born and highlights include an All New Transmission, All New Front Spool and Rear differential, Carbon Lower Arms, X-Low Shock, All New Motor Mount, New 8.0 steering plate, and a New Up-Stop function.

Carbon Lower Arms

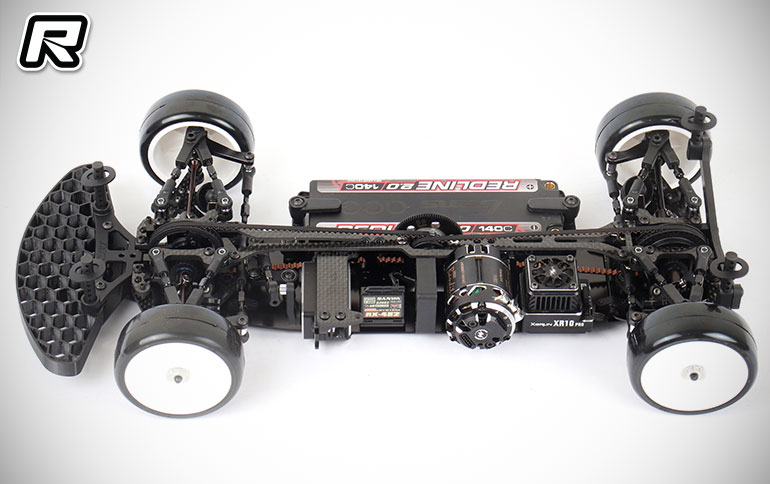

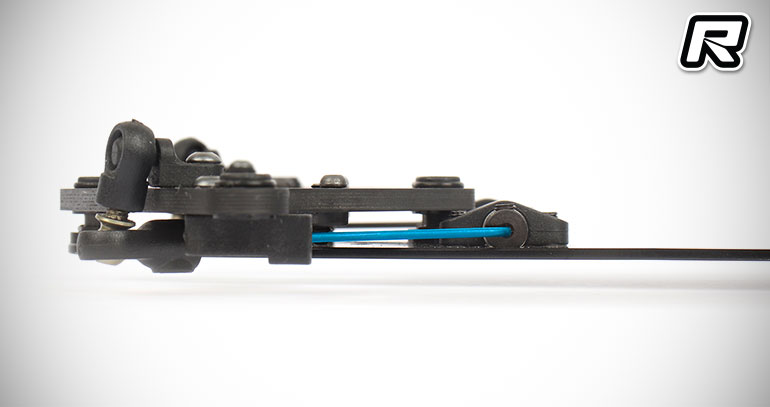

The all-new carbon fibre lower arms are available in two materials: a standard stiffness version included with the vehicle, and a stiffer version for high-grip or challenging tracks. The A11 lower arm shape ensures even stress distribution and effectively transfers the car’s weight to the tires, maximising overall mechanical grip. The new lower arm ball joint uses an O-ring for fixing, which makes assembly and maintenance easier. All 4.9mm ball heads are made of titanium to ensure maximum strength and optimal lightweight.X-Low Shock

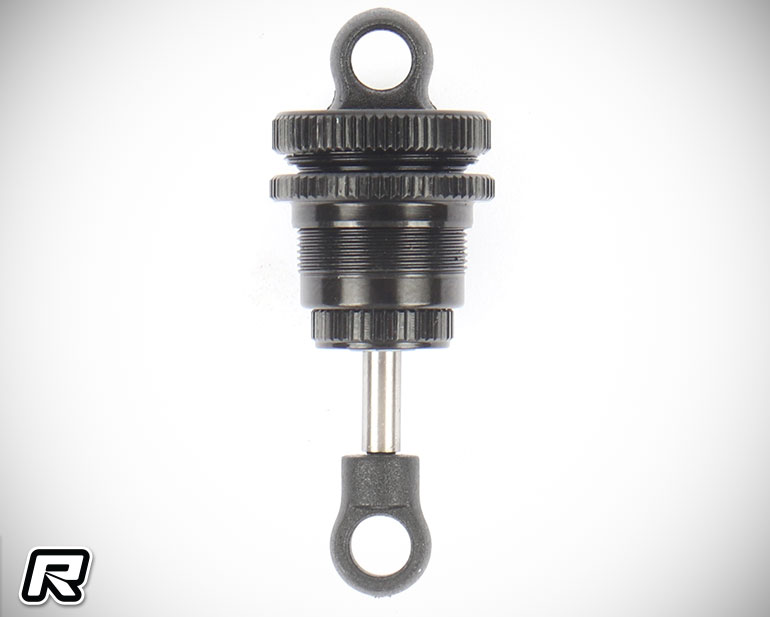

The A11 X-Low shock absorber is 1mm shorter than its predecessor, the A10-25 Ultra Short shock absorber, and its overall mounting height is reduced by 3mm. Therefore, the A11 can only use 17mm springs. The black body of the X-Low features a hardened coating, and an X-ring is used at the bottom of the oil seal to ensuresmooth and good operation. The shock absorbers on the A11 have been moved to a more concentrated location, with both front and rear shock absorbers moved inwards. Therefore, the A11’s shock absorbers are not only lower but also more concentrated. Like the A10, the front and rear shock absorber brackets have two screws to adjust the stiffness. When fully locked in the default position, the shock absorber brackets are at their stiffest, providing the most direct response.New Bumper

The new A11’s bumper not only increases the height but also minimises the area of the front chassis to reduce contact with the ground/carpet. On most flat tracks, the ride height can be set at 4.2~4.5mm without causing excessive friction on the

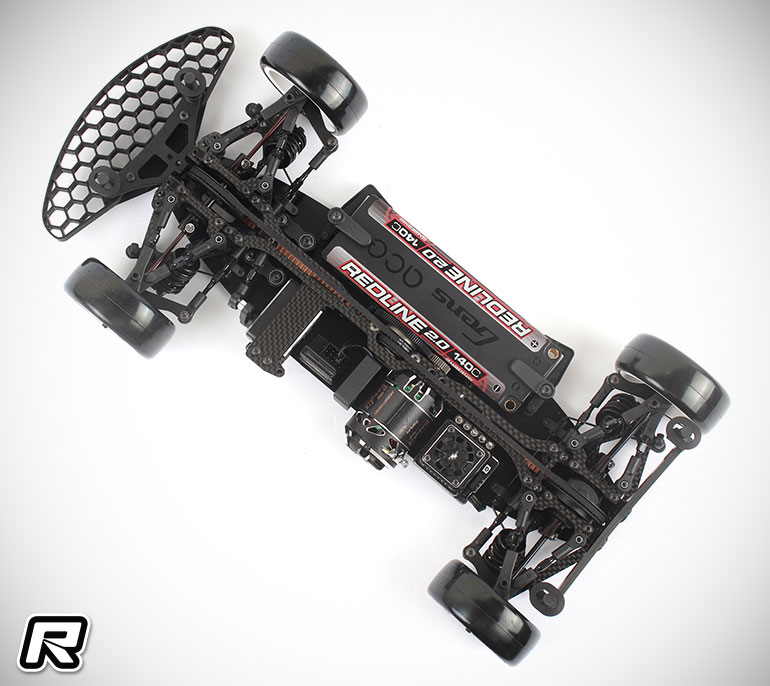

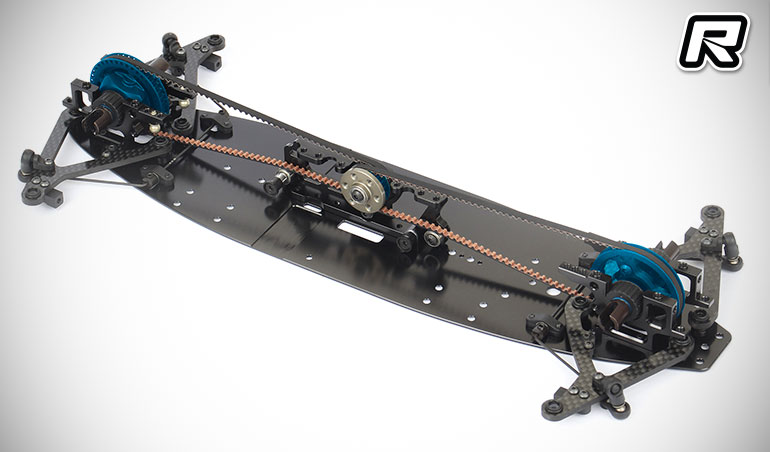

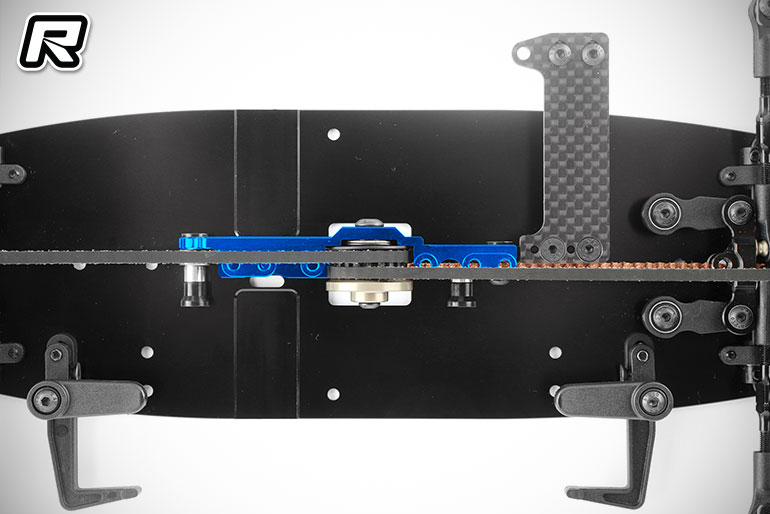

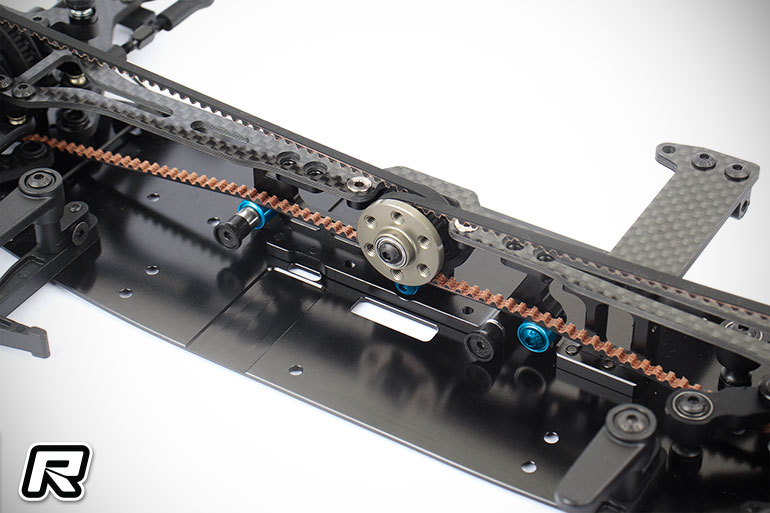

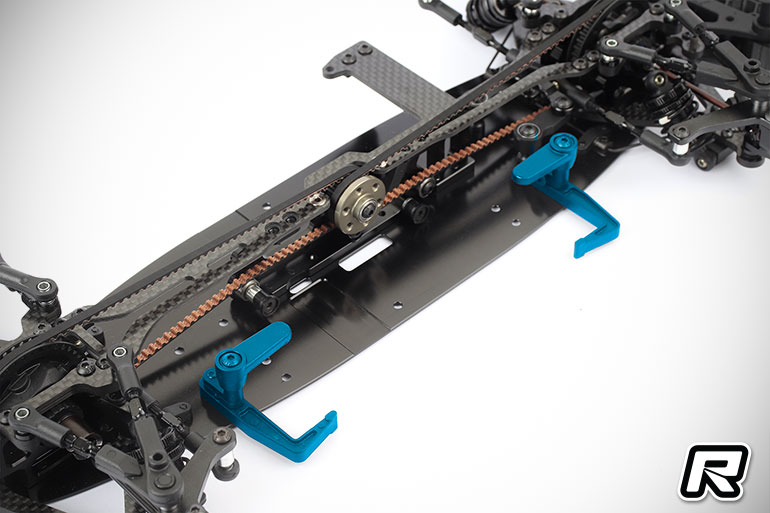

chassis.All New Transmission

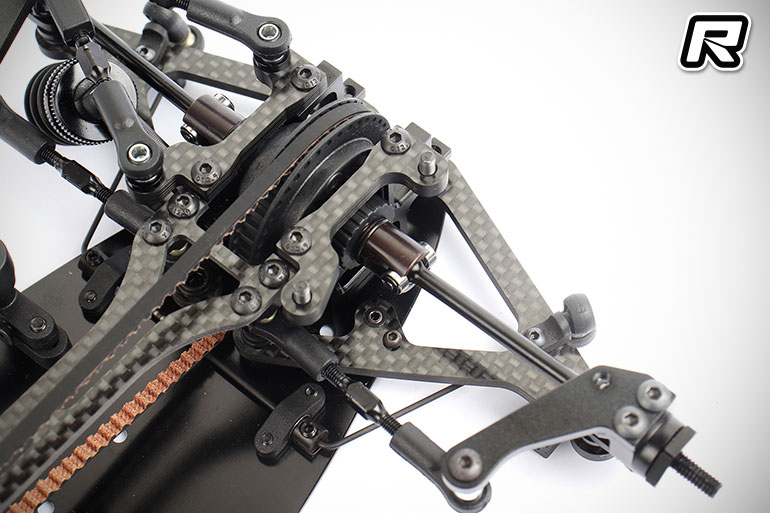

The A11’s all-new drivetrain uses a completely new gear ratio: 40T for both the front spool drive and the rear differential, 21T for the intermediate pulley, and a final drive ratio of 1.904. In long-term testing, this final drive ratio is suitable for STOCK

and Modified racing, and the larger pulleys result in lower belt curvature and smoother transmission.All New Motor Mount

Compared to the A10, the new A11’s motor position has been moved inward by 3mm. The new motor mount has bearings at the front, rear, and middle to adjust the belt tension, making the entire transmission system smoother. Another new feature is that the motor height can be adjusted using the third screw. When the top screw is used for fixing, the motor height will increase by 0.5mm, which can prevent the motor’s back cover from rubbing against the ground in some special cases.Ball Bearing Drive Shaft

The A11’s new transmission shafts all use smaller bearings instead of the previous C-caps, and both the front spool and the rear differential cup are made of S2 high- hardness steel, ensuring the highest level of smoothness and durability.All New Front Spool and Rear Differential

The all-new front spool shaft has adopted a smaller 6×10 bearing and undergone comprehensive weight reduction. The rear differential features a new bevel gear and design, using 5×8 small bearings internally to secure the rear axle and 6×10 small bearings externally. This achieves optimal smoothness and weight. Compared to aluminium alloy differential bodies, the all-plastic body is not only lighter but also prevents overheating, maintaining consistent performance throughout the entire 5-minute race.New Anit-Roll Bar

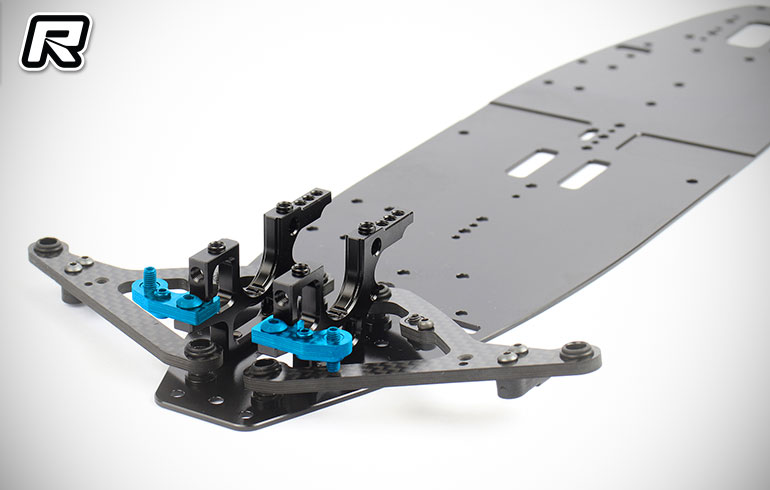

The A11 anti-roll bar is positioned significantly lower on the chassis compared to the A10, further lowering the overall center of gravity. The anti-roll bar passes under the lower arm and connects to the outermost part, allowing it to operate precisely. New Upright The A11 uprights are made of 7075-T6 aluminum alloy, which is high-strength and precise. The front and rear wheel hubs are identical for easy spare parts preparation. The new design allows the front to maintain a fixed angle when aligned with the drive shaft. The rear drive shaft is also made of 7075-T6 aluminium alloy, which is lightweight and high-strength.New 8.0 steering plate

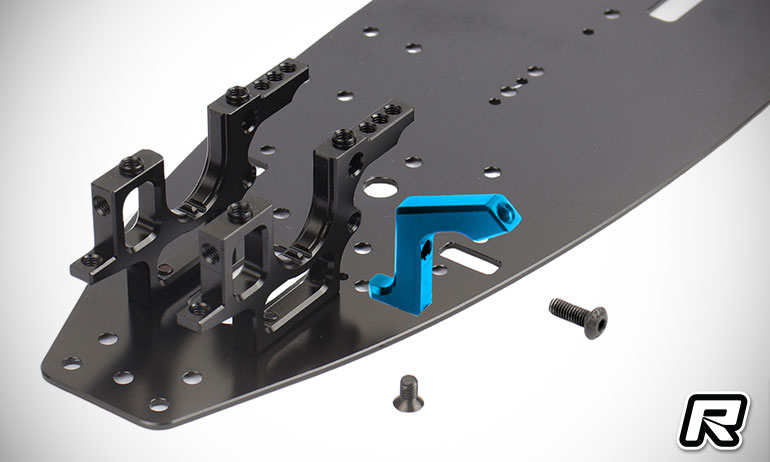

The new steering plate distance has been changed from 8.5mm to 8.0mm. This subtle change makes the A11's steering more responsive, especially in tight spaces, allowing for faster lap times. The new steering plate limits the maximum steering angle to 26 degrees, ensuring a suitable angle for various grip conditions.New Battery Mount

The new battery mount makes adjusting the battery tightness easier. Battery tightness plays an important role in the handling of the touring car. The appropriate position can be set with just a few screws and shims in the battery mount. The all-plastic battery mount further reduces the weight on the right side of the car to facilitate the use of large-capacity lipo batteries.New Up-Stop function

The A11’s design integrates the latest up-stop limit function on the bulkhead. This function can adjust the body roll and lateral grip by limiting the upper travel of the suspension arms. On tracks with high grip, reducing the front upper travel can increase front-end response and prevent oversteer. Reducing the rear upper travel can reduce rear grip and increase the response when switching sides. This is an optional accessory and can be purchased separately.

Source: ARC [arc-rc.com.tw]