Inside the factory – A visit to Hobbywing HQ

I have always enjoyed hearing people’s stories on how they ended doing what they do for a living. Getting the opportunity to visit the Hobbywing factory after covering one of China’s international races, on that trip to Shenzhen I would get to met Jack Zhang, the man who founded what has become one of the leading electronic manufacturers in our racing world. As I would learn from the visit, Hobbywing is a whole lot more than the company we all know for making the motors and ESC that allow us to go racing. Its impressive growth to a company with over 1,000 employees all grew out of an RC enthusiast’s need for a product to allow him enjoy his hobby. While getting to see the production lines off which come all the XeRun ESC and motors, that would complete a clean sweep of all four electric IFMAR World Championship titles on offer in 2025, it was actually the behind the scenes work, research & developing, and testing that makes these products that was the real highlight of visiting not one but two locations that make the final products roll off the production line. While Salton Dong is the global public face of Hobbywing, travelling to major races providing technical support to team drivers and customers, there wouldn’t be Hobbywing if it wasn’t for Jack finding himself in a predicament in his own passion for RC Helicopters. And it was a chance introduction to Salton on an RC forum that would prove pivotal to the brand becoming the force they are today in RC racing. The expertise since helping them to expand into markets you might be surprised to learn of.

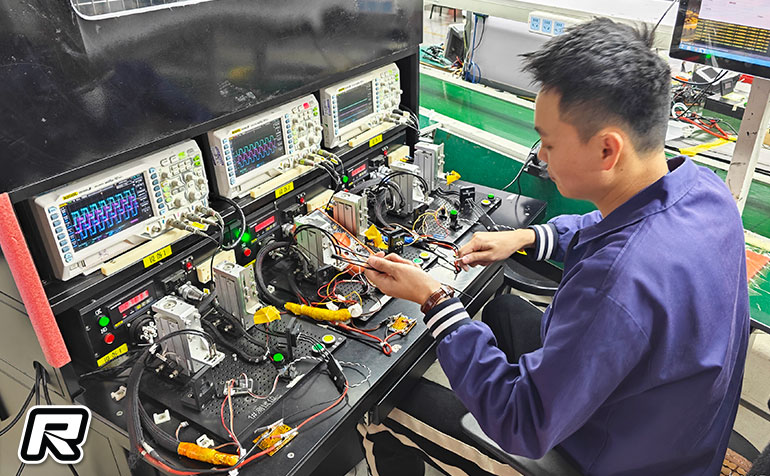

Arriving at the Hobbywing headquarters, the first thing I would learn was that while this was once their main production facility I would have to wait til the following day to actually see motors in production. The growth of the brand has meant they had to open a new factory about a 2-hour drive away, and standing looking at the massive 4-story HQ building I couldn’t but think how many motors & ESCs do they make!! Now where all the company admin and R&D is carried out, and where more than 300 people turn up for work each day, the only production in the building is in their own clean room. Suiting up for this controlled environment with the very nice Jennie, who arranged my visit, together with Salton as my official guide we all looked like we were going to bake some sweet goodies. Once through the clean room entry procedure, I was taken through how multiple chips and components are loaded into machines and come out as the brains of the ESC in the form of circuit boards in this heavily automated process. From here we moved to another floor and this was where for me all the good stuff was to be discovered in various rooms/departments.

From walking through the floor I quickly learned that what started as making electronics for radio controlled cars has since opened up opportunities to provide that technology to scooter & electric skateboard manufacturers and well known electric moped & motorcycle manufacturers plus drones, and some very big ones at that. One could mistake sections for a motorcycle dealer, these 1:1 scale bikes waiting for their turn on the numerous dyno set-ups as the latest throttle controllers are tested for things not just performance related but how that power delivery feels for the rider. Also a huge manufacturer of motors for drones, and I am not just talking drones that the likes of team driver Bruno Coelho captures some great aerial views of the latest track he is racing at, but monstrous ones that are used for things like agriculture applications. The test area for this was impressive, big caged and sound proofed rooms where the motors & propellers are run for hours and to destruction to ensure that such drones stay in the sky and meet aviation standards.

Getting back to my chat with Jack for moment, expecting this to be his opportunity to give me the corporate spiel I didn’t really come all the way to hear, I couldn’t have been more wrong and I only wish I had had more time to hear more of the stories behind the growth of Hobbywing. The story actually all started through his heli flying. With 3D flight becoming big, at the time it was a US brand that had the best ESC for this but getting this to China was super expensive so Jack thought why couldn’t he produce one in China for himself and his friends to enjoy cheaper flying. He reached out on a forum for help and that’s where he met Michael Liu whose electronics background has been to key to the foundation of Hobbywing. After that success a friend of Jack’s asked him about making an RC Car ESC and he thought yeh that should be easy however it would prove more challenging that expected because helicopters don’t have a need for brakes. Again searching for knowledge he went back on to forums where he would come across a local racer, that guy being Salton who then worked in the computer industry. In telling the story of the first tests they did, the pair laughed about the number of spur gears they went through. Knowing how to make the speed change they under estimated the brake function. Salton explaining the initial version of braking software was like an on/off switch and at the end of the straight such was the force that the spur gear was the weakest link and lived a very short life. With them soon figuring out the parameters needed, this partnership would grow stronger and stronger with Salton able to leave his role in the computer industry and become a consultant to Hobbywing, that arrangement remaining to this day and Jack very keen to highlight and acknowledge the role Salton has played in the growth of the company. Given how the RC side of the business came about, joking with Jack that I suppose they got into electric skateboard and scooters because a friend asked, Jack said that is exactly what happened. A skating friend’s desire for an electric skateboard led them into that side of the business too and that has since branched into other forms of human mobility such as mopeds.

Back on the tour while many of you will have seen IPX rating on products, my own learning about IPX ratings coming when purchasing a head torch for ultra trail running in Ireland where it rains a lot, have you ever thought how this is tested? Well you guessed it, Hobbywing has a whole department full of specialist machines for putting products through all kinds of weather and conditions simulations. Ones for rain and water testing, ones for extreme heat and cold conditions, and ones for exposing them to dust and dirt. Speaking of water, greeted by a large water tank in one room I made the cool discovery that Hobbywing make their own range of electric hydro foil boards, they even have branded lifejackets to match!! Asking Salton if he could arrange a discount for one, on finding out the price I put that idea on hold, these water toys ain’t cheap!

Wrapping up Day 1 of the visit in their show room it was nice to see the brands journey in the sport highlighted on a story board along the wall and such key moments as Andy Moore becoming the first World Champion they signed to race their products in 2012. This was the beginning of the then little known Chinese brand becoming force in the then golden age of 1:10 Electric Touring Car. After the few hours of exploring and learning how much goes into R&D, Day 2 would start with Jason He picking us up for the drive to the new factory. Jason is another familiar Hobbywing face who is part of our RC circus that travels around the world for big races and a super nice guy to boot.

Arriving at the new factory again the scale of the place is impressive, with over 700 workers again over multiple floor levels & production lines this place was a hive of activity. Each floor we would be joined by the manager of that particular production process who took us through the process and answered my many questions. The bottom floor is an impressive line up of rows of CNC machines turning out all the necessary alloy parts that on the floors above will be assembled into finished motors & ESCs before being packaged and shipped around the world. On the tour of the motor lines I would discover it is the racing motors for cars that are the most difficult to produce because these have to meet the exact specs of their IFMAR, EFRA and ROAR Approval. Quality of the components key as a number of manufacturers have found out the hard way. While we see a lot of automation in manufacturing these days, winding motors is still a fully manual process and very interesting to see being carrier out.

With rolls of varying gauge cooper wire filling one end of the floor, I asked the question as to how many kilometres of wire they get through each year but unable to give specific we all agreed it in the very high digits. One observation I made on the assemble floor is how often each stage of the process is tested and checked, Salton keen to highlight this was one of the big advantages of being a true manufacturer rather than depending on outsourcing.

Having to wrap up the visit so as to catch my flight back to our somewhat smaller and less impressive HQ, Red RC would like to give a special thanks to Jennie for arranging the visit, Salton and Jason for answering my many questions and being good company over the 2-days, and of course Jack for the very nice welcome and very enjoyable chat to kick of the tour. While I have given just an overview of my experience of the factory, rather than go into the detail of screw A goes into hole B, Hobbywing is working on a series of videos to show you the individual processes that goes into the making of its motors and ESCs.

Taken with my phone, Hobbywing more than happy for me to snap away as we toured each building, here are a few more images from the visit –