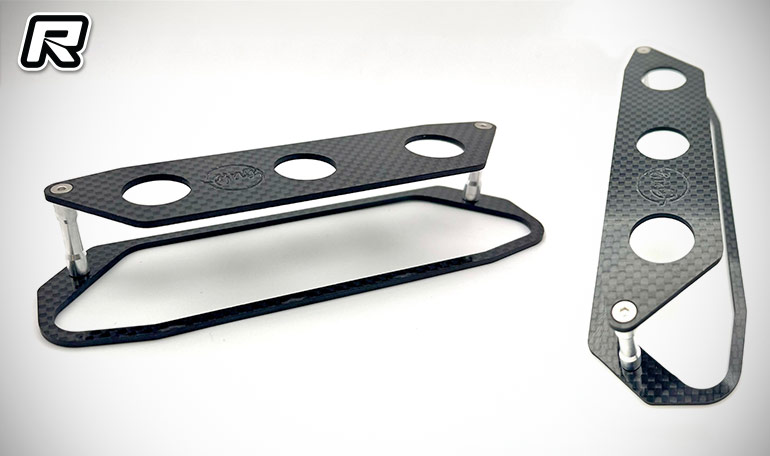

ONG Camber | Ride Height | Stroke & Rebound Gauges

New from the ONG brand of 4-time Offroad World Champion Davide Ongaro comes three essential set-up tools for offroad racing. All made from aluminium with an anodised ONG green finish, the camber gauge can measure between +3 to -10 degrees. The long reach ride height gauge measures in the range of 3mm to 42mm. The Shock Stroke & Rebound Gauge allows easy measurement of shock length while mounted on the vehicle during suspension setup and supports stroke from 60mm to 150mm.

Source: ONG [davideongaro.it]