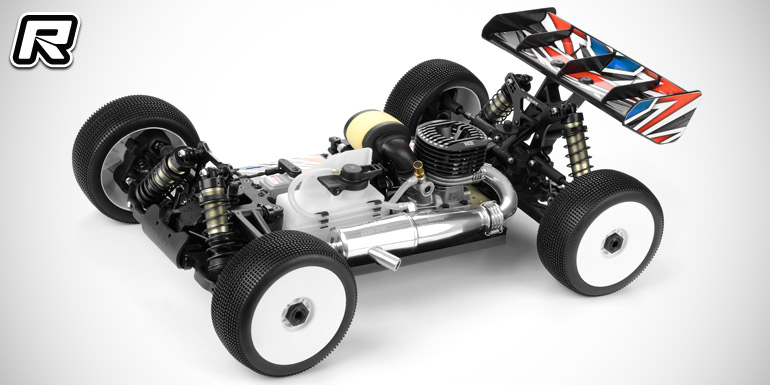

Xray XB8’20 1/8th nitro buggy kit

Xray have introduced the latest incarnation of their highly successful XB8 1/8th scale nitro buggy platform, the XB8 2020. This year’s variant of the company’s IFMAR vice World Championship and EFRA European Championship winning buggy features some subtle updates and improvements that still target pretty much every aspect of the buggy, be it the chassis, drivertain or suspension. And so the 2020 variant builds on a redesigned 3mm 7075-T6 aluminium chassis that is 4mm longer for improved overall stability while the included hard composite radio box increases chassis rigidity and handling consistency. The harder composite material also retains its stiffness in very high temperature conditions.

New for 2020 is also an updated front shock tower that now offers a second row of upper shock mounting holes with the higher positions make for increased traction and are thus recommended for low-traction and rough conditions while the lower set of holes increase the buggy’s stability on high-bite tracks.

On the drivetrain side of things the 2020 kit features an all-new longer rear centre driveshaft to match the long wheelbase chassis while CV-style Hudy spring steel driveshafts are now included for both the front and rear suspension to assist with increased traction and easier maintenance and servicing. In addition the front steering block ball-bearings are updated to accommodate the CV axles. The central driveshaft assemblies also feature protective rubber boots, thick 3mm pins, and protective locking rings.

The 2020 variant of the XB8 includes rear wheel hubs with a +2mm off-set while the front features the +1mm off-set wheel hubs. The ultra-lightweight 17mm wheel hex drive hubs are CNC-machined from Swiss 7075-T6 aluminium and they are specially machined to reduce rotating weight while guaranteeing wobble-free wheel mounting.

Both front and rear differentials on the XB8’20 are now identical for easier maintenance and servicing and all feature higher capacity cases, stronger diff pins, and large internal gears with more teeth for improved differential action, consistency and overall reliability. The larger volume of the differentials and the shape of the gears teeth help reduce oil overheating for better consistency in long mains or when running in high temperature conditions. Coming with the kit is also a new 48T centre spur gear for improved acceleration.

The high-torque clutch features a new lightweight flywheel that was redesigned to offer a reduced mass for quicker engine response and clutch engagement. The high-torque clutch provides smooth, continuous power transfer from the engine to the driveline. With the included hard springs, the clutch engages higher in the RPM range, resulting in more controllable power during acceleration while still maintaining good engine response and performance on jumps. The Swiss 7075-T6 aluminium clutch shoes are small, lightweight, and designed for engagement during the entire travel of the shoe. The shoes are also less sensitive to wear which results in improved lifespan. In addition the smaller diameter allows the flywheel to be better protected when landing large jumps, so there is a reduced chance of accidental engine stoppages.

Also part of the package is an updated brake system. To improve the braking efficiency and to ensure constant braking characteristics, ultra-efficient pre-glued brake pads are now included in the XB8 kit. The centre upper plate was redesigned to clear the larger 48T spur gear included in the kit. The laser-cut, precision-ground steel brake disk allows for fade-free braking in conjunction with the special high-grip brake pads installed on the laser-cut brake plates. The brake disk is small, slim, and very light. The precision hand-grinding allows true, wobble-free rotation. Brake inputs are transferred precisely to the brakes thanks to the rigid, high-precision machined brake cams. Both brake disk and brake pads are specially heat-treated for maximum lifespan.

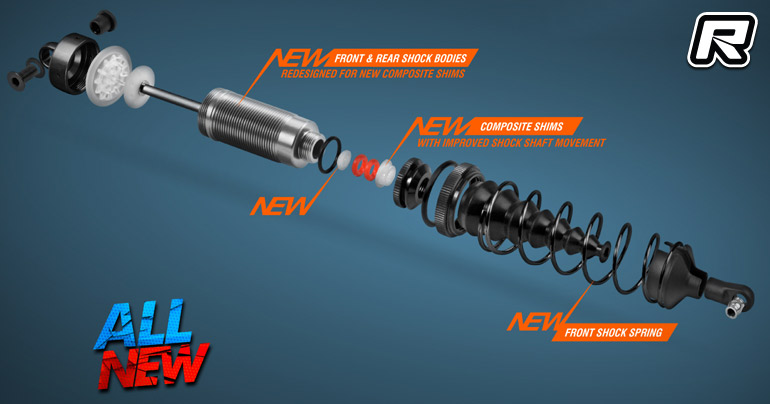

The XB8’s shocks were improved with updated shock bodies redesigned to fit the new composite lower shims for improved shock shaft movement. The shock caps feature four bleed holes for easier building and more precise rebound control. The longer shock shafts allow more suspension travel and multiple shock membrane choices are available to tune the suspension to a wide variety of track conditions. The shock bodies are hard-coated in a titanium colour and feature a 1-piece aluminium shock cap. The XB8 now also includes the 4-dot front springs.

The XB8 2020 also includes a hard composite radio box that is more rigid in higher temperatures to improve the precision of the servo movement and to allow for more room for the receiver battery pack. The optional soft composite radio box increase chassis flex. This can help improve handling characteristics in some low- to medium-traction conditions. The 1-piece electronics assembly is very compact and can be quickly and easily removed for servicing and cleaning. It requires undoing only a few screws from the bottom of the chassis to remove the entire electronics assembly from the car. The large, moulded radio box features a very clean design and layout that places the weight in key areas for proper balance. The receiver battery is placed along the front centreline of the chassis, and the receiver is placed on its side in the rear. The easy-access radio box is mounted on the side of the car and is secured by the fewest possible amount of screws.

The fuel tank was redesigned to comply with the new rules featuring the transient jet that ensures the internal volume of the fuel tank cannot be changed by pulling the fuel line. The extra-strong fuel tank features an integrated floating stone filter that ensures that the fuel pickup will always be in the correct orientation, even if the car isn’t. This fuel pickup system will allow fuel to continue to flow to the engine, even while waiting for a marshal to reach the inverted car and put it back on its wheels. Internal baffles ensure that the fuel will always be in the area around the fuel line intake so even during large jumps the fuel will be constantly supplied to the engine. The fuel tank cap features a very strong spring which ensures the cap will always close after refuelling, and the specially designed rubber gasket perfectly seals the fuel tank and ensures no fuel will leak outside.

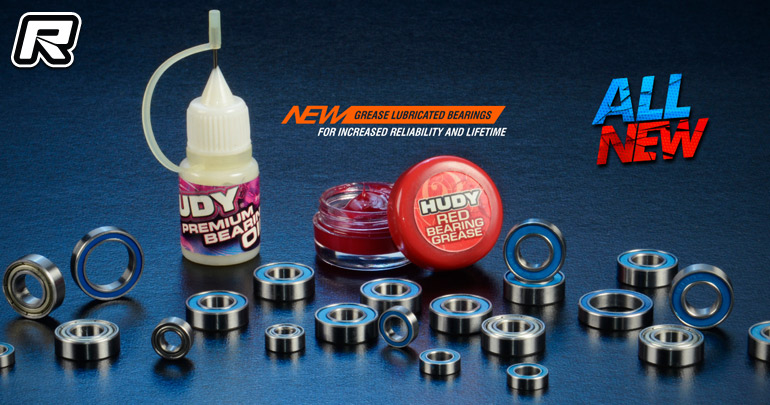

A full set of 24 high-speed ball bearings are used throughout the XB8 drivetrain. All-new grease lubricated bearings are included for the pinion gears and diffs to increase reliability and lifespan, especially in dusty conditions. The remaining bearings are degreased and oiled with AeroShell Fluid 12 to reduce drag and maximise driveline efficiency.

The 2020 kit is rounded out by a completely redesigned rear wing. The new shape increases the stability of the car in all conditions and is legal under the new IFMAR wing specifications. Made from a strong special composite mixture, the wing was designed to survive severe abusive and extreme crashes while keeping its shape.

New features:

– All-new 4mm longer chassis for improved stability

– Longer centre rear driveshaft to match the new chassis

– All-new front shock tower with lower second row of upper shock mounting positions for tracks requiring higher corner speed and more stability

– All-new lightweight flywheel for faster engagement

– Hard clutch springs for improved engagement

– Ultra-efficient pre-glued brake pads for improved braking efficiency and consistent braking characteristics

– 48T spur gear for improved acceleration

– Redesigned centre upper deck to fit the 48T centre spur gear

– All-new fuel tank with transient jet for more consistent tank pressure and to ensure constant volume

– All-new redesigned IFMAR-legal rear wing increases stability in all conditions

– Front and rear CV drive shafts included for increased traction and easier maintenance

– All-new greased bearings for pinion gears and diffs for increased reliability

– +2mm offset wheel hubs for rear suspension

– New shock bodies revised to accept new composite shims for improved shock shaft movement

– Includes 4-dot front shock springs

– Includes hard composite radio box for chassis stiffness and reliability in hotter temperatures, improved precision of servo movement and more space for the receiver battery pack

Find the full presentation here.

Source: Xray [teamxray.com]