Xray T4F’21 FWD touring car kit

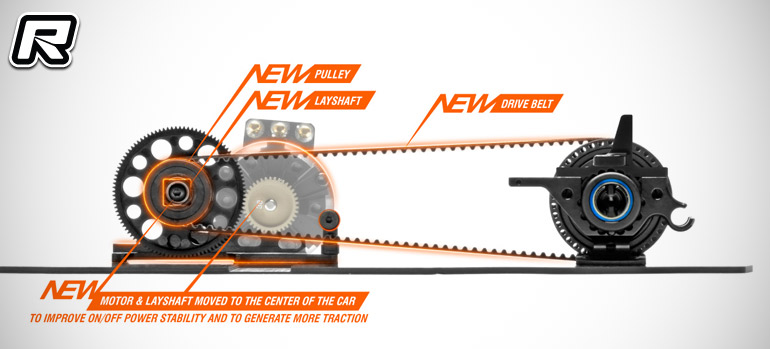

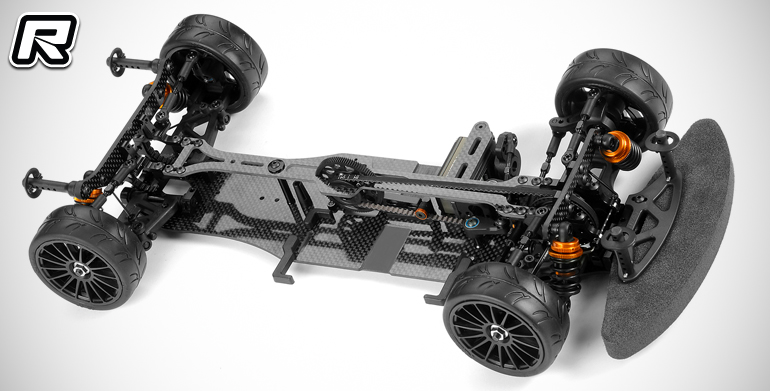

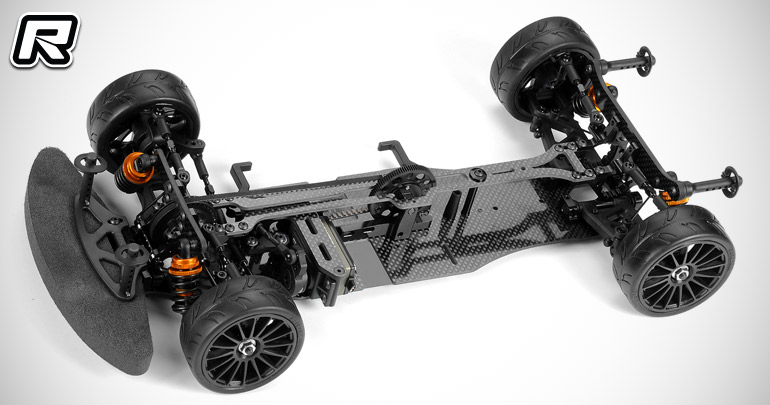

Following a couple of teaser images Xray have finally unveiled the latest edition of their successful T4F front-wheel drive touring car. The T4F 2021 is based off of the T4 2020 all-wheel drive touring car and features an all-new mid-motor layout, meaning Xray have dropped the former front motor layout for the nowadays more common mid-motor design. It also means the FWD car shares about 90 percent of parts with its 4WD family member, making stocking parts a lot easier. As for the design, the T4F 2021 features an all-new central drivetrain that moves the motor and layshaft to the centre of the car to improve on/off power stability and to generate more traction.

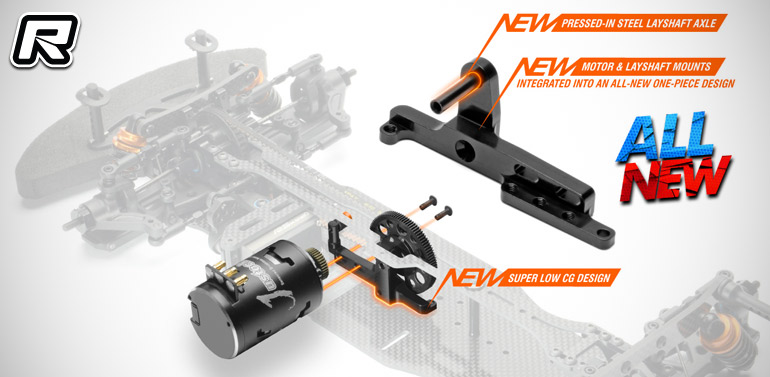

The motor and layshaft mounts are integrated into an all-new one-piece design that is placed in the absolute centre line of the chassis. The new motor mount features a factory attached steel layshaft axle that is positioned in the middle of the chassis. The motor is located in front of the layshaft to match the unique weight distribution needs of a FWD platform. The motor mount is designed to have super low CG design but still robust enough to resist bending in serious crashes.

The motor mount is fixed on the chassis with four screws. One is positioned behind the layshaft axis, with the other three screws being located in front. These screws can be removed for further chassis flex adjustments. In addition the motor mount also integrates with the battery backstop holder.

The all-new aluminium layshaft is strategically CNC-machined to minimise rotational masses without compromising strength or integrity. The precision layshaft includes two pressed in bearings to minimise slop and reduce drivetrain vibration. The layshaft features a super narrow design and a new square hub profile to interface with the new 20T pulley for the drive belt. The pulley is secured by an O-ring or the C-clip depending on the driver’s preference.

The all-new chassis was completely redesigned to accommodate the new centre drivetrain system and the long arm suspension components. The new layout moves the main bulkheads towards the centre by 1mm and adds mounting holes for the new long arm suspension mounts. The 2.2mm thick chassis is CNC-machined from premium-grade graphite material and was developed for all asphalt surface conditions. The narrow chassis is only 84mm wide with a variety of chassis flex adjustments that help to generate exceptional traction and give excellent steering characteristics. An aluminium chassis will become available as option part for all higher grip surfaces.

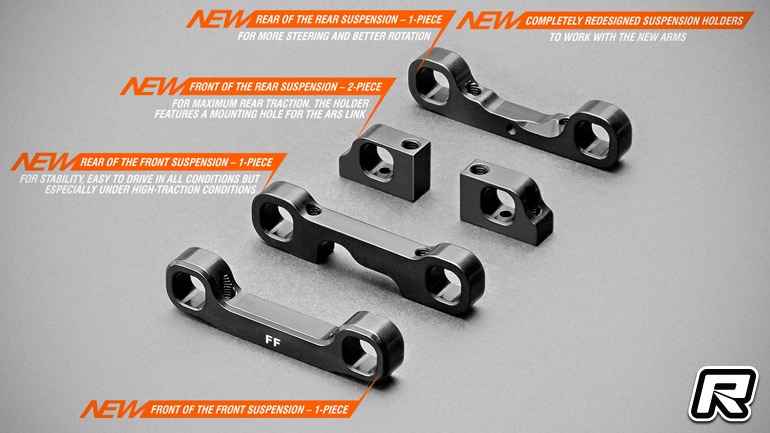

The new suspension arms were completely redesigned. At 7mm longer than the previous generation, they help create more grip in low traction conditions and improve stability on higher traction surfaces. The suspension arms feature a standard shock mounting position as well as a new 4mm lower position to lower the CG – the latter is accessible by using the optional ULP shock towers. The lower mounting position improves the stability of the car in the chicanes and in technical corners and improves steering response. The rear arms feature a new design to accommodate the standard rear suspension and the optional ARS suspension using the same arm. Different hardnesses of arms are available, each optimised for different racing conditions.

The all-new suspension holders were completely redesigned to work with the longer arms. Made from premium Swiss 7075 T6 aluminium and coming black anodised, there are two types of the suspension holders, each specifically designed and chosen to provide the required characteristics – stability, traction, and flex. The FF, RF, and RR mounts are of a single piece design while the FR mount is of a 2-piece design with mounting positions for the ARS links.

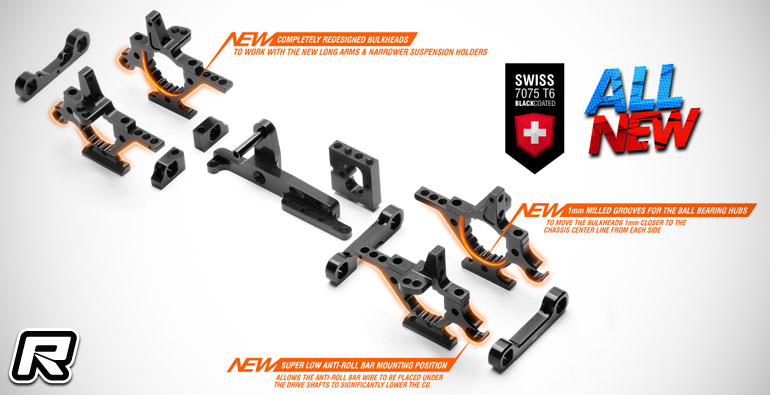

The all-new bulkheads were completely redesigned to work with the new long arms and narrower suspension holders. The bulkheads feature a super low anti-roll bar mounting position that allows the anti-roll bar wire to be placed under the drive shafts to significantly lower the CG. The bulkheads feature new milled grooves for the ball bearing hubs to move the bulkheads 1mm closer to the chassis centre line from each side. Additional cut-outs create extra clearance to move the inner suspension pins closer to the centre line.

All-new upper clamps were redesigned to work with the new narrow bulkhead locations. The upper clamps feature the same 1mm milled grooves for the ball-bearing hubs. The upper clamps have been further milled to remove unnecessary material to reduce their size and weight.

The Swiss 7075 T6 aluminium steering plate was redesigned to significantly reduce play of the entire steering system, making the steering more responsive and precise. The bearings are now factory pressed into the steering plate which eliminates play in the assembly.

The all-new anti-roll bar system moves the anti-roll bar wires under the drive shafts to lower the CG as much as possible. The new anti-roll bar system features redesigned front wire bar length, lighter anti-roll bar bushings, smaller 3x6x2.5mm bearings and all-new lower composite anti-roll bar ball joints to create a super lightweight assembly with low CG. The wobble-free anti-roll bar system is mounted to the front & rear bulkheads via bearings from the outside of the bulkheads for extra-smooth movement and quick & easy changes and adjustment. The roll bars rotate in ball-bearings for maximum precision and free movement. Anti-roll bar height is adjustable via a screw. A complete range of anti-roll bar thicknesses are available for tuning, with the front 1.4mm and rear 1.3mm anti-roll bars included as standard. Anti-roll bars have laser-engraved markings for easy identification.

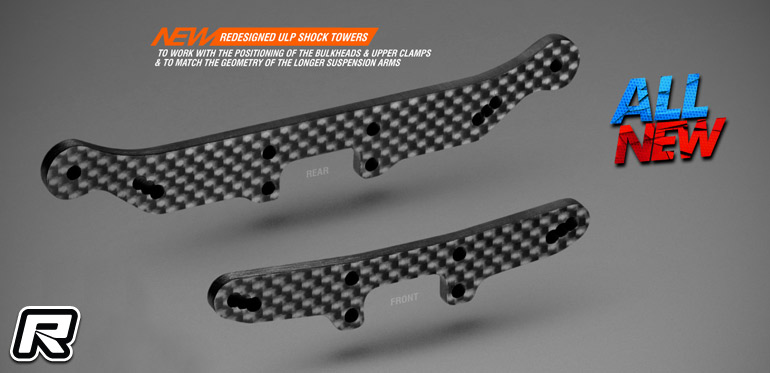

The all-new ULP Ultra Low Profile shock towers were redesigned to work with the positioning of the bulkheads and upper clamps and to match the geometry of the longer suspension arms. Machined from premium-grade 3.0mm graphite, the shock towers are super lightweight and very compact.

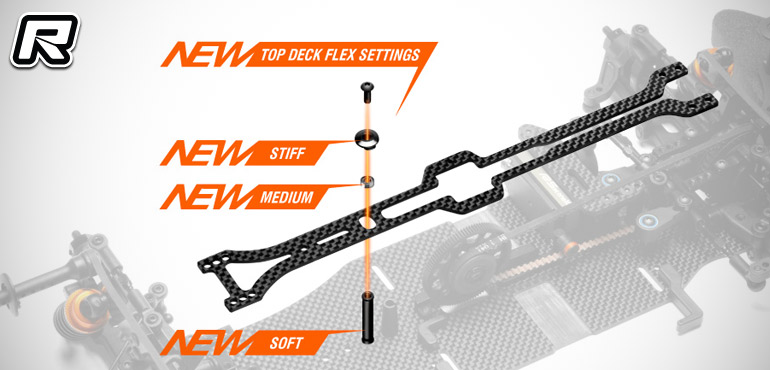

The all-new top deck was designed to work with the new centre layshaft location in the middle of the chassis. Made from 2.0mm graphite material, the shape of the top deck has been specifically designed to achieve maximum traction and great steering characteristics at the same time. The top deck is perfectly symmetrical to achieve the ideal, consistent flex behaviour.

The unique top deck flex setting allows easy adjustment of the flex between 3 different characteristics of soft, medium and stiff.

With the BPA Body Position Adjustment system, the entire bumper area was redesigned to feature upper and lower composite bumpers. The foam bumper design accommodates the adjustable eccentric body posts as well as the standard fixed body posts. The redesigned lower bumper has an updated shape with edges that prevent the bumper from touching the surface when the car is rolling.

Key features:

– All-new FWD platform based on the T4’20

– All-new drivetrain layout with centralised motor position

– Central layshaft location for more consistent on-power/off-power balance

– All-new motor position in front of the layshaft for the improved weight balance for FWD class

– Super narrow top shaft utilises new 20T pulleys and pressed-in ball bearings to minimise space requirements

– Narrow suspension holders and longer arms improve traction and corner speed

– All-new 7mm longer suspension arms feature two shock mounting locations; the lower position combined with ULP shock towers reduce chassis roll and improve stability in high traction conditions

– All-new super low anti-roll bar mounts and new compact linkage components helps lower the vehicle CG

– All-new redesigned anti-roll bar system features new front bars, smaller bushings and shorter ball joints designed for the new low CG mounting locations

– All-new symmetrical top deck shape provides clearance around new central drivetrain pieces while maintaining even side to side chassis flex characteristics

– All-new central motor mount positioned directly on chassis centreline for consistent chassis flex

– All-new black anodised lower bulkheads are moved 1mm inward to increase clearance for new long arm suspension geometry

– All-new narrowed upper clamps to match lower bulkheads and integrate with new shock towers

– All-new lighter graphite floating servo holder and taller servo posts redesigned to work with new suspension and driveline geometry

– Compatible with most T4’20 spares and option parts

View the full presentation here.

Source: Xray [teamxray.com]