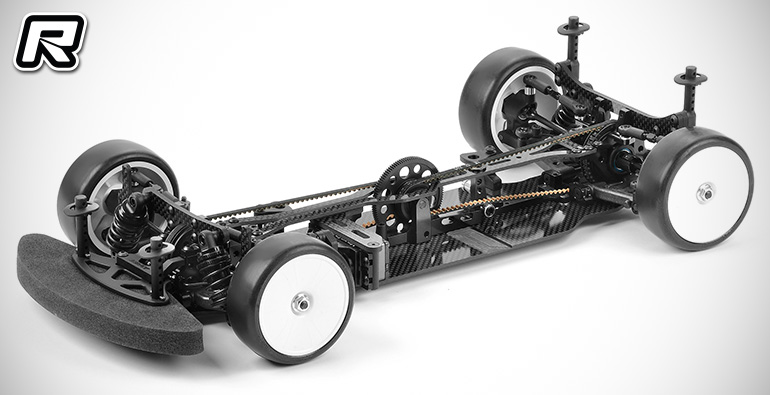

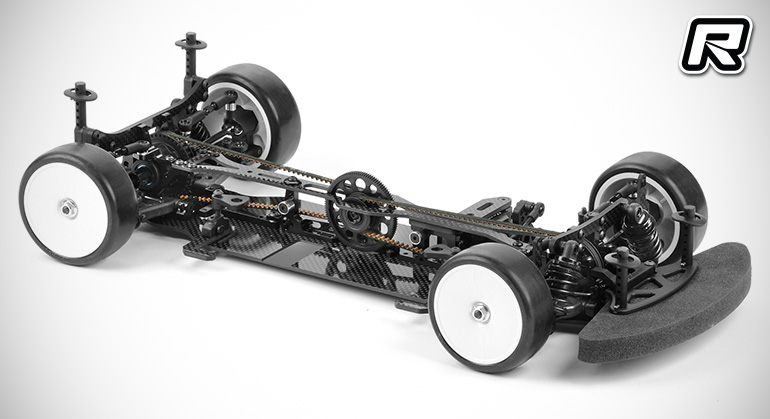

Xray T4 ’21 1/10th touring car chassis

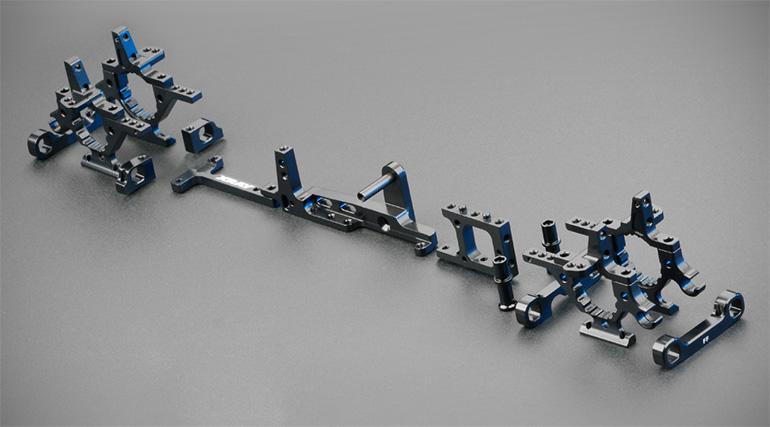

Having revealed a lot of the new for 2021 T4 in videos in recent weeks, Xray have finally released the complete details of their new touring car. With only some small updates instead of a major redesign, the new car is available in a choice of graphite, flex aluminium or solid aluminium chassis. The new chassis has been designed for the new motor mount, new T-brace and new RF suspension holders. The top deck is also new with a narrower front section that improves steering characteristics and forward traction and has a revised rear profile for improved motor clearance for spec class motors. The all-new motor mount is machined as a single piece for increased strength and features new integrated tensioner to precisely set the rear belt tension. A new T-brace is included for improved central flex characteristics and for additional control. New bulkheads with improved rear arm clearance when using the high roll centre positions are supplied as are the new RF suspension holders with centering pins for more accurate and consistent rear toe-in setting. In the transmission, steel outdrives are used for the solid axle for improved durability and the 52mm ECS drive shafts are also included for increased stability and cornering speed.

2021 All-new Features

– Improved T4 platform incorporates updates and popular option parts

– Available in choice of Graphite, Flex aluminium or Solid aluminium chassis

– New chassis designed for new motor mount , new T-brace and new RF suspension holders

– New top deck with a narrower front section improves steering characteristics and forward traction

– New top deck with revised rear profile for improved motor clearance for spec class motors

– All-new motor mount machined as a single piece for increased strength

– Motor mount features new integrated tensioner to precisely set the rear belt tension

– New T-brace for Improved central flex characteristics and for additional control

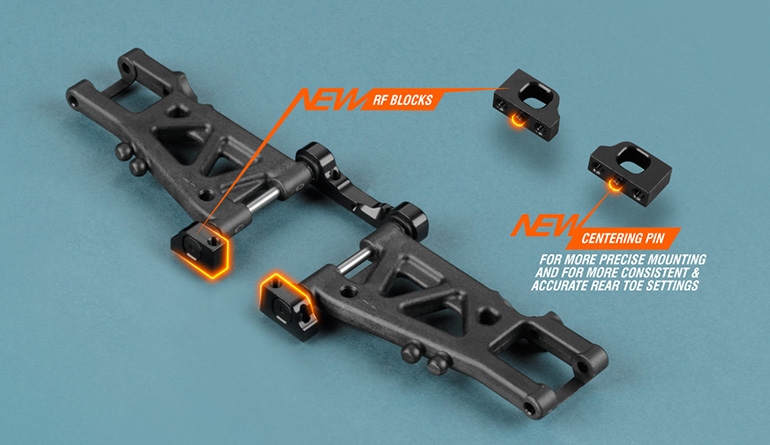

– New bulkheads with improved rear arm clearance when using the high roll centre positions

– New RF suspension holders with centering pins for more accurate and consistent rear toe-in setting

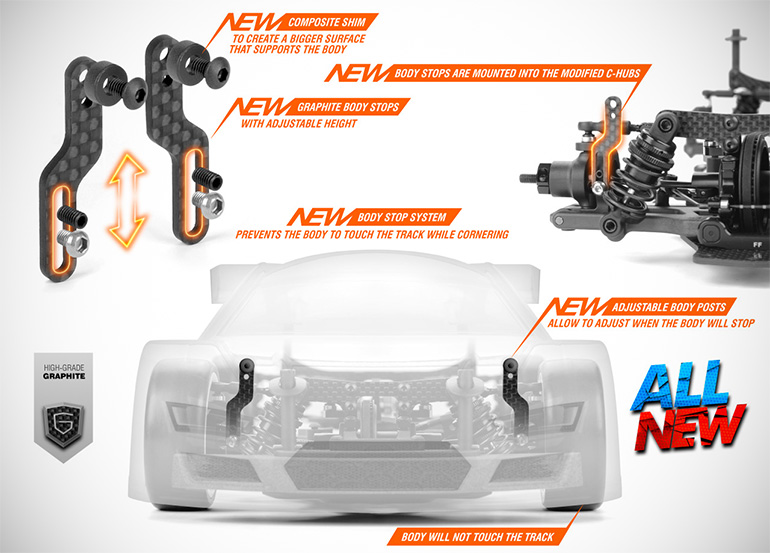

– All-new adjustable front body stops prevent body collision with track while cornering

– Steel outdrives for the solid axle now included in the kit for improved durability

– 8mm steering plate included for easier control in corners

– 52mm ECS drive shafts included for increased stability and cornering speed

– Front upper bumper brace for increased protection in serious crashes and improved durability

– 2.5-2.8 front and 2.6 rear springs now included as the most popular combination used

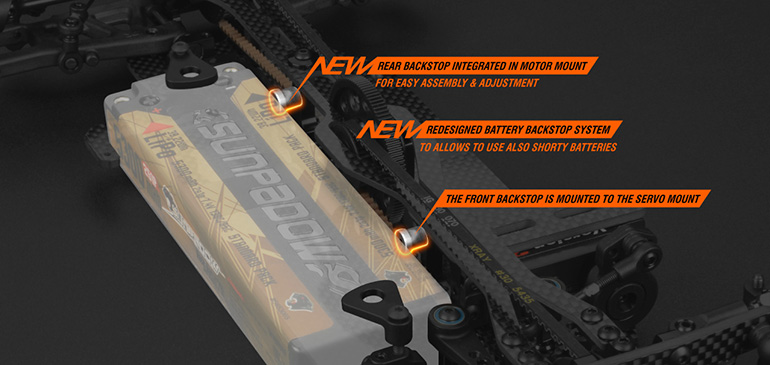

– New tweak-free, fully-adjustable Quick Battery Mounting System without tape

– New battery backstops integrated into the motor mount and compatible with shorty battery packs

– All parts are now black anodised including shocks and steering system

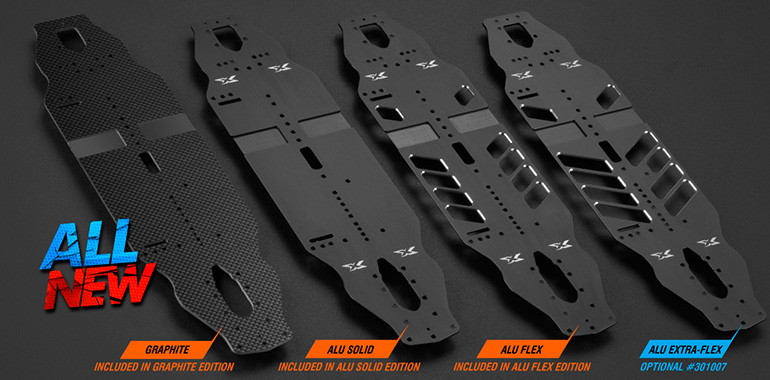

Graphite & 2 Alu Editions

The T4’21 platform was tested for performance improvements across all track conditions to have the car at the highest competition level out of the box. But even with this goal, there are still enough differences in track conditions that it can require different components for maximum levels of performance. To allow the customer to choose their ideal starting point, there are three versions of the T4’21: the Graphite, Flex aluminium and Solid aluminium Edition. Each version features all the same components except for the chassis plate.

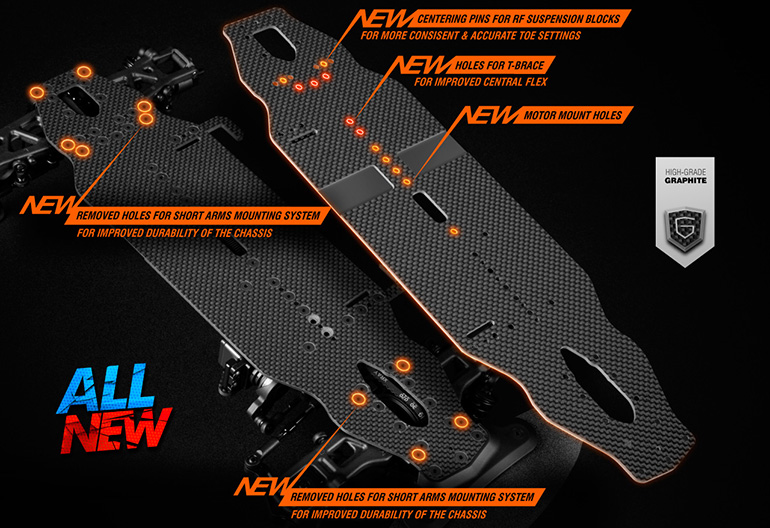

Chassis

All-new chassis is redesigned to work with the new motor mount, T-brace and features holes for centering pins for RF suspension blocks. The holes for short arms mounting system are removed for improved durability of the chassis. Retained from the previous year, the mid motor chassis layout is designed to accommodate the new centre drivetrain system and the narrow mounts for the long arm suspension. There are three chassis alternatives to choose from when selecting the kit, 2.2mm graphite or 2.0mm aluminium flex chassis or 2.0mm aluminium solid chassis.

The 2.2mm thick chassis is CNC-machined from premium-grade graphite material. This chassis is developed for all asphalt conditions. The narrow chassis is only 86mm wide with a variety of chassis flex adjustments that help to generate exceptional traction and give excellent steering characteristics. The 2.0mm thick aluminium flex chassis is CNC-machined from premium Swiss 7075 T6 aluminium, then black coated and laser engraved. The ultra-narrow chassis is only 84mm wide and features special cut outs that provide the chassis flex characteristics suitable for a variety of the medium grip surfaces. The bottom of the chassis is tapered to reduce contact between the chassis and the ground while turning to improve cornering speed. The 2.0mm solid aluminium chassis is available for high traction conditions such as US black carpet tracks.

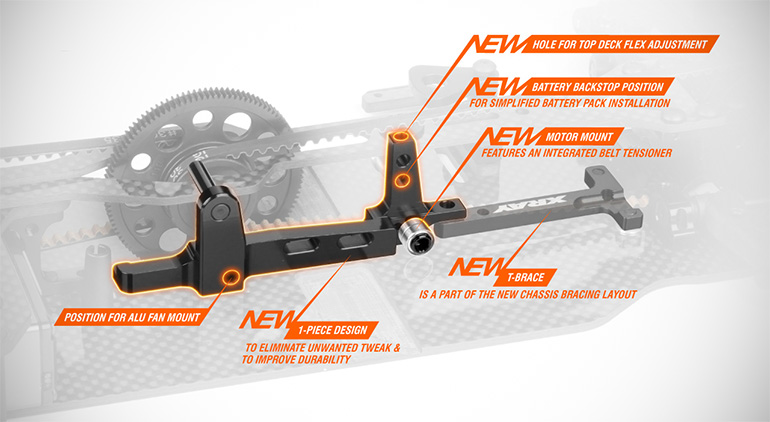

Motor Mount

New motor mount is machined as a single piece and now features an integrated belt tensioner to control the rear belt tension more precisely. The motor mount is also part of the new chassis bracing layout that can link the mount, T-brace and chassis for more flex control choices. The motor mount is made from 1 piece instead of 2 pieces (motor mount + post in previous version) to eliminated unwanted tweak and to make the motor mount more durable. The motor mount also includes the mounting provisions for the battery backstop for simplified pack installation.

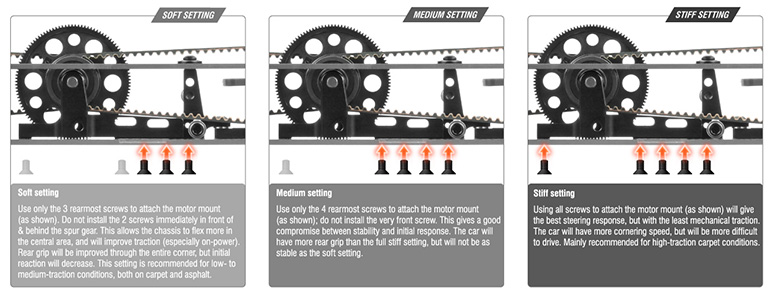

Motor Mount Flex Settings

The motor and layshaft mounts are integrated into a one-piece design that is placed in the absolute centre line of the chassis. The new motor mount features a pressed-in steel layshaft axle that is positioned in the middle of the chassis with the motor located to the rear of the layshaft. The motor mount is designed to have super low CG design but still robust enough to resist bending in the serious crashes. The motor mount is installed on the chassis with 5 screws. One is placed in front of the layshaft axis, and the other 4 screws are located to the rear and can be removed for further chassis flex adjustment. Machined from premium Swiss 7075 T6 aluminium and black anodised.

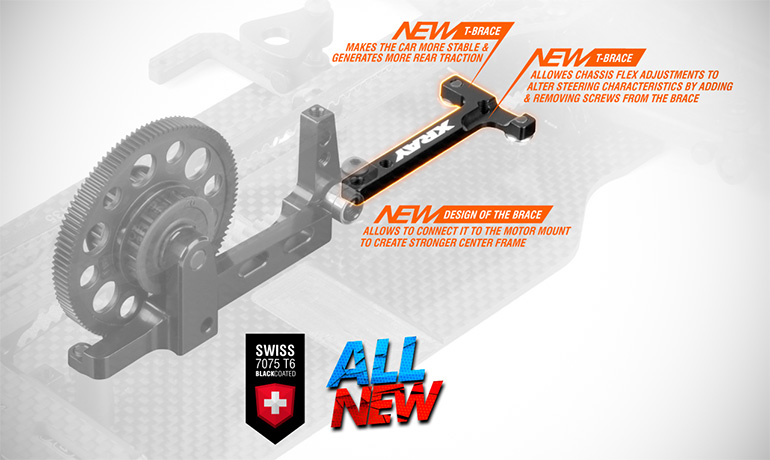

T-Brace

The previously optional T-brace is now included as a standard feature in the T4’21 as it was used in almost all conditions on both asphalt and carpet surfaces by team drivers and customers alike. The brace made the car more stable, generated more rear traction and allowed chassis flex adjustments to alter steering characteristics by adding and removing screws from the brace. The updated T-brace can now be connected to the motor mount to create an even stronger centre structure which makes the car more stable and easier to drive while pushing the pace even faster.

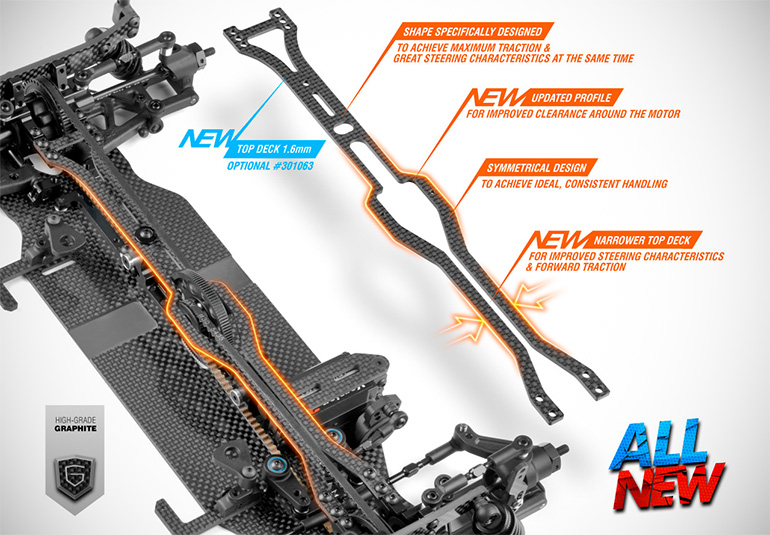

Top Deck

The new top deck is narrower in the front section for improved steering characteristics and forward traction. The profile of the rear section was updated for improved clearance around the motor for better fitment to allow a wider range of gearing and motor positions typically found in spec class racing. The top deck was designed to work with the new centre layshaft location in the middle of the chassis. Made from 2.0mm graphite material, the shape of the top deck has been specifically designed to achieve maximum traction and great steering characteristics at the same time. The top deck is perfectly symmetrical to achieve the ideal, consistent flex behaviour. Optional 1.6mm graphite top deck is recommended for use in low- to medium-traction conditions with the optional alu chassis.

Bulkheads

New bulkheads are refined with improved rear arm clearance when using the high roll centre positions without rear arm modification. Bulkheads were completely redesigned in 2020 to work with the long arms and narrower suspension holders. The bulkheads feature a super low anti-roll bar mounting position that allows the anti-roll bar wire to be placed under the drive shafts to significantly lower the CG. The bulkheads feature 1mm milled grooves for the ball bearing hubs that moved the bulkheads 1mm closer to the chassis centre line from each side. Made from premium Swiss 7075 T6 aluminium, black anodised.

Body Stop System

The body stop system is an all-new feature. The graphite battery stops are mounted into the modified C hubs with a height adjustable position to control when the body touches the graphite stops. Thanks to this new system, the body can be placed lower in front to improve high speed steering and stability of the car.

Battery Holders

New tweak-free, fully adjustable Quick Battery Mounting System offers simply and secure battery installation without tape and without adverse effects on chassis flex. The new system controls the positioning of the pack in the chassis while at the same time reducing the battery pack’s impact on chassis flex, resulting in more consistent handling and stability. Smart battery holders are specifically designed for LiPo batteries and are reinforced for harder impacts. The battery holders prevent the batteries from moving under racing conditions and crashes.

Battery Backstops

The battery backstop system was redesigned for use with the increasingly common shorty batteries. Now integrated in motor mount for easy assembly and adjustment. The battery backstop prevents batteries from moving in a crash. In the front, the backstop is mounted on the servo mount; in the rear, the motor mount.

Bumper Brace

The new composite front upper bumper brace is included in the kit to prevent chassis damage in serious crashes. The brace was designed to distribute the forces from a big impact to reduce damage to the chassis plate.

Suspension Holders

New RF blocks feature a centering pin for more precise mounting and for more consistent and accurate rear toe settings.

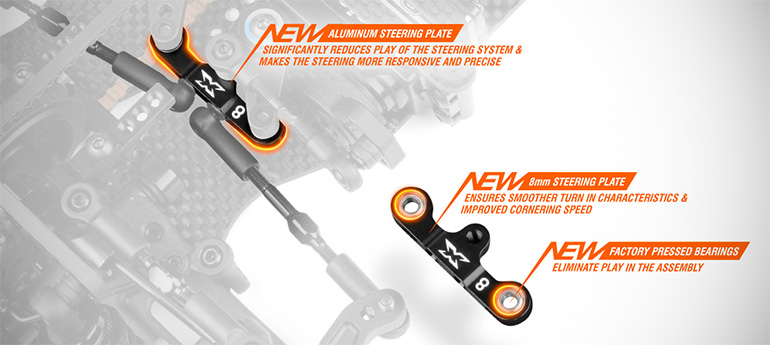

Steering Plate

The 8mm steering plate is now included in the kit. Based on the racer feedback, the 8mm plate was preferred for both modified and spec classes in nearly all conditions and surfaces, and is now standard in the kit for improved performance right from the box. The main advantage of the 8mm steering plate is a smoother turn in characteristic and improved cornering speed. The Swiss 7075 T6 aluminium steering plate was designed to significantly reduce play of the entire steering system, making the steering more responsive and precise. The bearings are factory pressed into the steering plate to eliminate excess play in the assembly.

Steel Outdrives

New steel outdrives for the solid axle are now included in the kit as another improvement in out of the box performance based on customer feedback. The steel outdrives replace the previous standard composite outdrives.

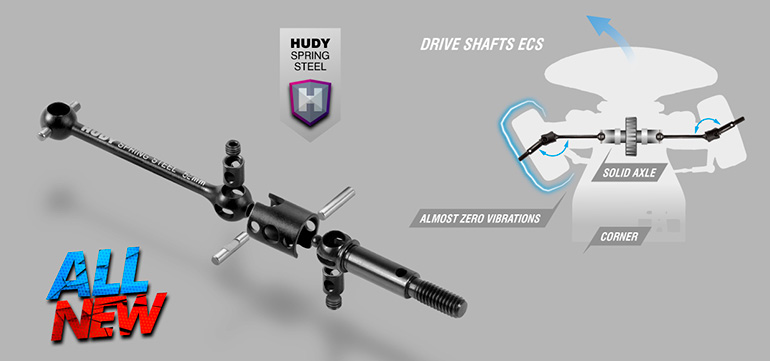

ECS Drive Shafts

The 52mm ECS drive shafts are now standard in the T4’21 based on the racing experiences over the last year. The 52mm was preferred by many spec class racers in most conditions to improve the car performance right from the box, increasing stability and cornering speed. 50mm and 51mm ECS drive shafts are still available to tune to particular track conditions.

The Xray ECS drive shafts equalize the speed between the drive shaft and the wheel. With a unique 2-piece joint between the axle and the wheel, an extreme wheel turning angle is divided into two shallower angles without causing binding. Regardless of cornering speed and wheel angle, the inner wheel will not bind or vibrate. Drive through the corner is more stable, more precise, and easier.

With the ECS drive shafts, wheel vibrations and noise are decreased to minimum, steering is increased, and cornering speed & smoothness are noticeably increased. Drive shafts are exclusively manufactured from special world-renowned, top-secret, self-developed HUDY Spring Steel™. The drive shafts are strategically lightened – see the hollow end of the dog bone – to guarantee the lowest possible weight without compromising strength or durability.

These specially lightened drive shafts can only be manufactured from special HUDY Spring Steel™ which was developed for extreme racing conditions. The drive shafts have been additionally hand-ground for maximum precision and to provide true rotation and unbinding drivetrain operation.

View the full presentation here.

Source: Xray [teamxray.com]