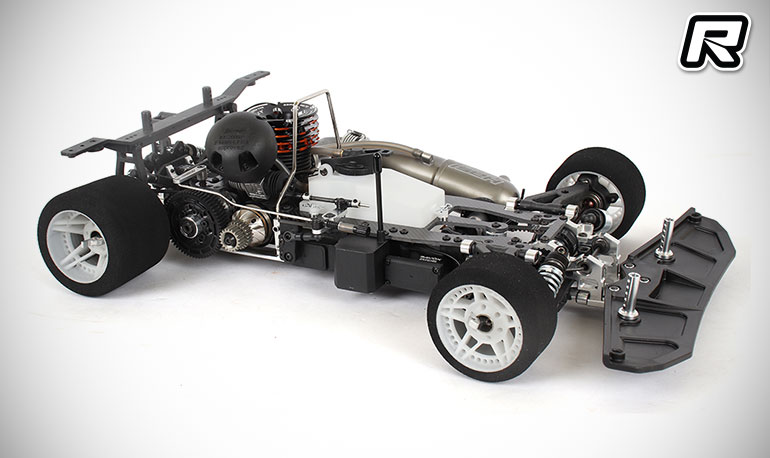

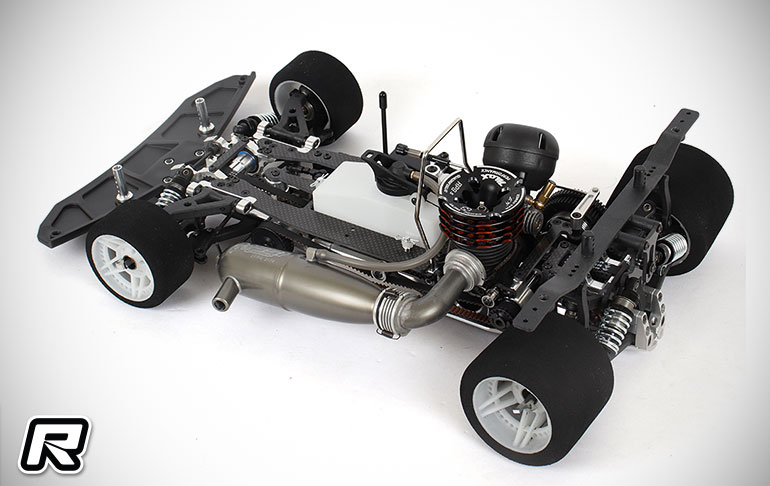

ARC R8.4 1:8 Onroad Chassis

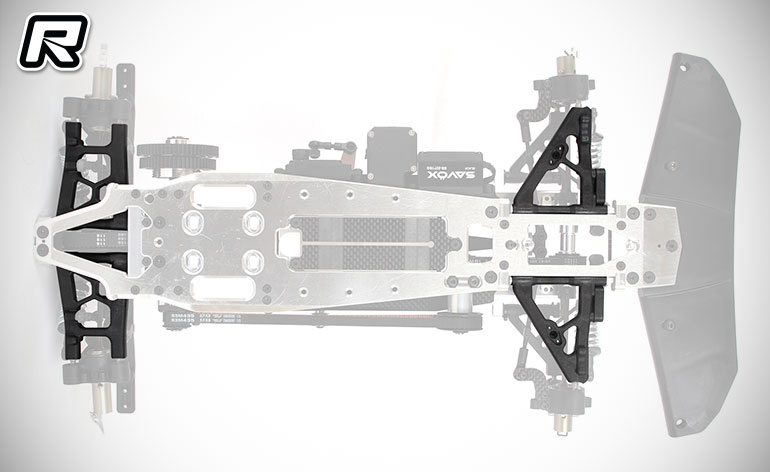

ARC has released its latest 1:8 Onroad Nitro racing chassis for the 2023 season, the R8.4. Based on the R8.3, the R8.4 features numerous improvements to deliver a massive step in overall performance. The car features an all-new chassis with a stiffer mid-section while they have lowered the engine position on the R8.2 LCG by removing the material below the engine area. The new R8.4 chassis has no milling below the engine to help increase chassis hardness and improve rear side bite. All-new lower suspension arms front and rear lower the suspension arm design is the result of extensive during the 2022 racing season in various traction levels around the world. The new arms are thinner all around but features reinforced areas in the rear lower arm for better impact resistance. They give significantly more corner speed and makes the car much easier to drive. These improved characteristics have been proven across various traction levels and at varying tire diameters.

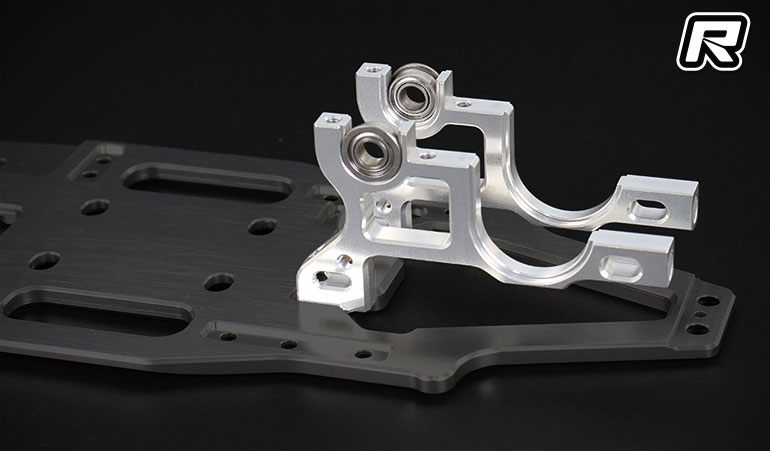

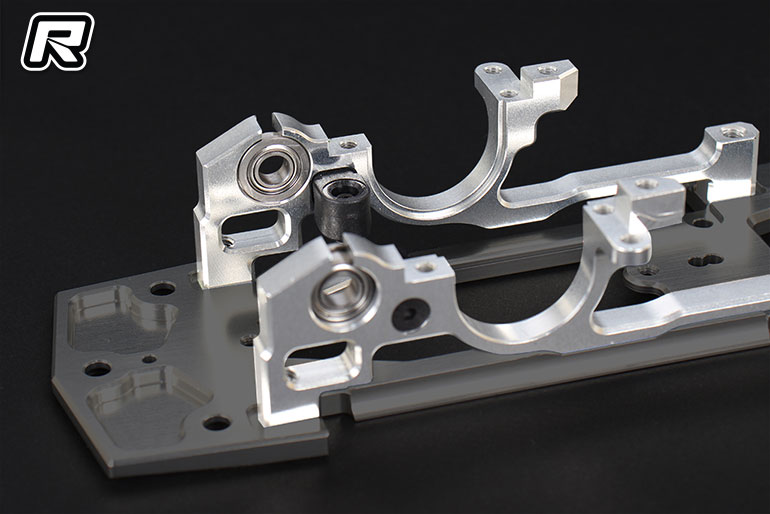

With the middle belt being the longest belt, this can result in the belt flipping over the rear pulley under super high traction conditions. A new middle belt tensioner features an additional ball bearing just above the rear pulley for significantly reduced belt deflection and

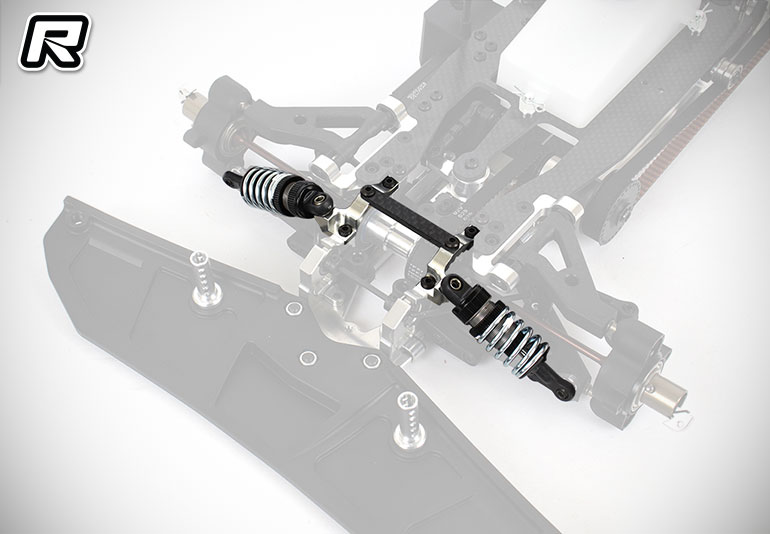

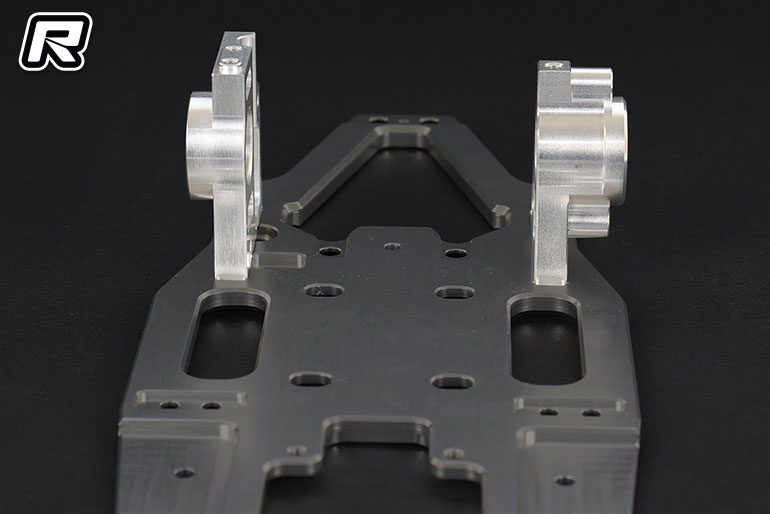

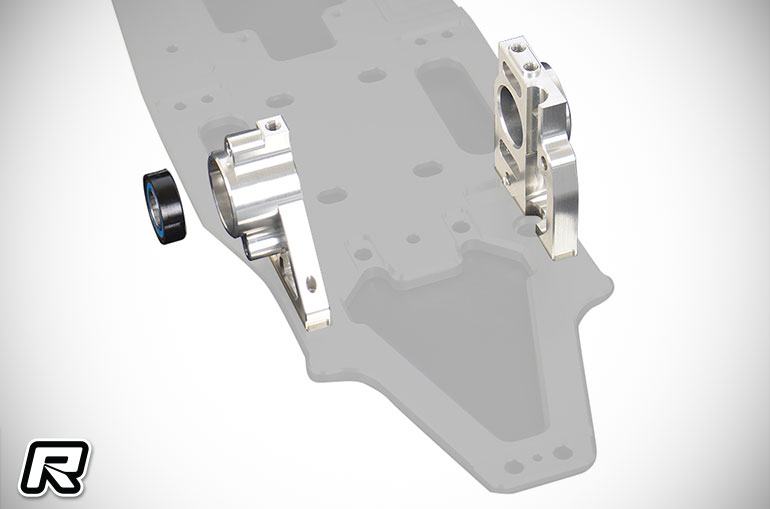

prevents the belt from disengaging even under the harshest racing conditions. An option part released late last year, the adjustable shock base is now standard on the R8.4, the adjustable shock base can be used to fine-tune the shock angle by adding or removing 0.5mm or 1.0mm shims below the shock absorber. New front and rear bulkheads now feature recessed mountings for the anti-roll bar ball

bearings. This increases the contact surface area for the anti-roll bars, bringing more precision to the chassis’ handling response.

There are 5 different anti-roll bar stoppers for R8.4 – 2.2mm,2.4mm, 2.6mm,2.8mm, and 3.0mm – with each stopper being tailored specifically for each anti-roll bar thickness. Doing this ensures precise suspension operation, reduce tweak and greatly improved handling

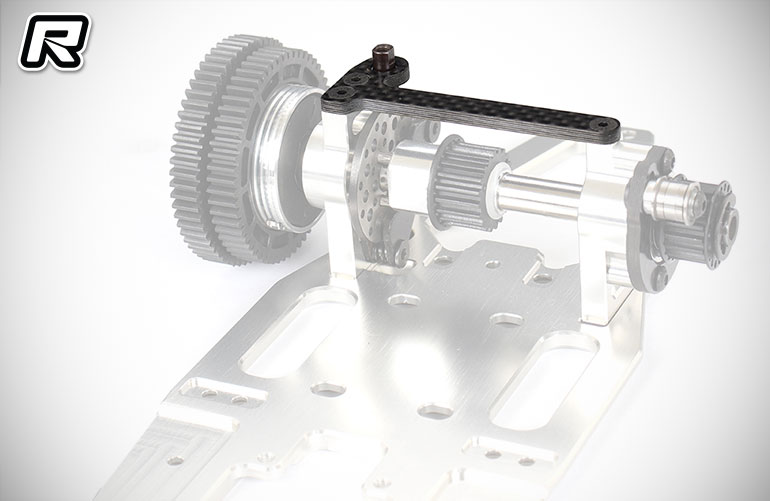

consistency, especially during long finals. The new main 2-speed shaft bulkheads are designed to move each side ball bearing as far

outside as possible to reduce stress on the ball bearings. Combined with a carbon fibre stiffener above the bulkhead, flex in this area is significantly reduced to increase shaft rotation stability and increase the efficiency of the transmission. The new bushing design for the main shaft comes with two dimples that slot inside the bulkhead. This prevents both the bushing and the bearing from spinning at the same time, further improving drivetrain efficiency and the overall durability of this assembly.

Source: Team Titan [team-titan.com.tw]