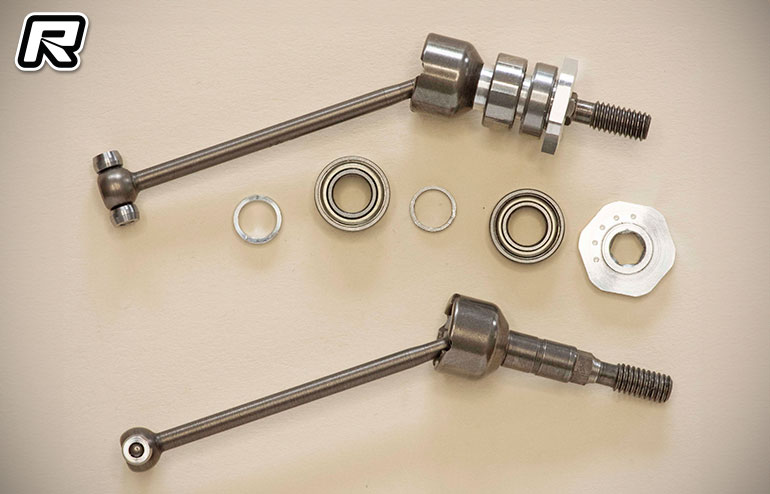

MiBorg X4’24 ‘RJS’ innovative inner joint

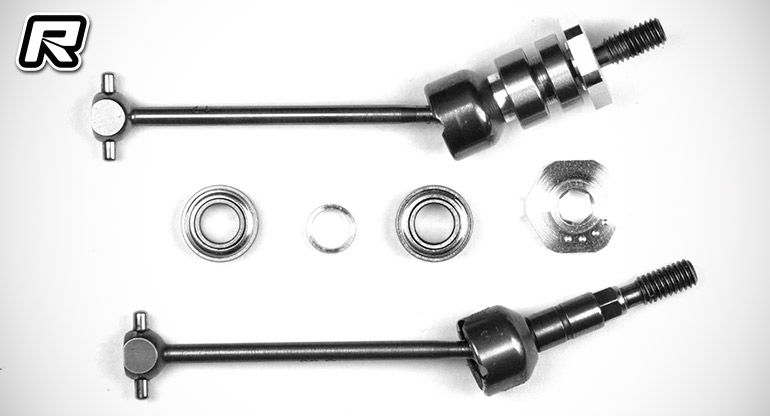

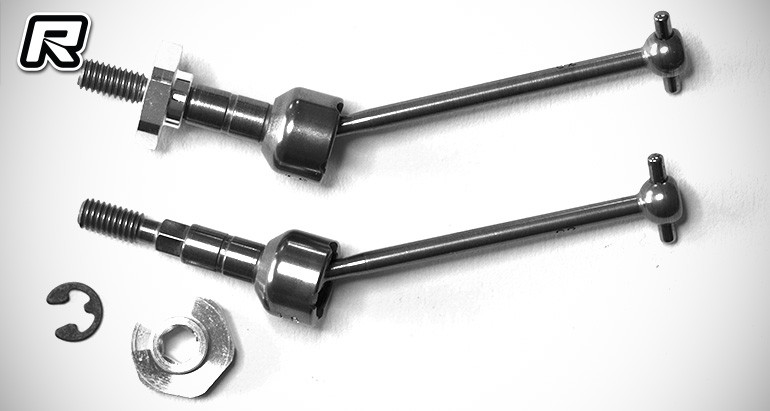

French RC driveshaft specialists MiBorg has released its ‘RJS’ innovative inner joint for the Xray X4 ’24 1:10 Electric Touring Car. This unique system drastically reduces the friction effect generated by the driveshaft in roll movement of the car. It is a more robust and simplest solution compare with bearing competitive solutions : no bearing, no e-clip and no maintenance. The 2 mm idler in the drive shaft head is lubricated for life with specific lub. RJS is compatible with Xray “BB” spool or differential cup and combined with innovative RCV driveshaft.