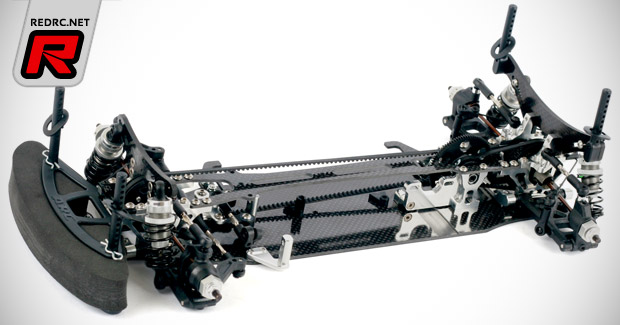

Titan ARC R10 double-joint CVDs

Titan RC have released this latest option part for the ARC R10, a pair of double-joint CVDs. The shafts are made from hardened spring steel, which is super durable and provides a smoother transmission on the R10. The new design features 4 holes in the middle joint, which not only reduces weight but also make it easy to apply lubricant into the joint, while a reenforced spring ensures you never lose the connecting pin under any condition.

Source: Titan RC [team-titan.com.tw]